What factors are most important to you when selecting a frame for your next project? Should you prioritize strength and durability, or are weight and flexibility more your speed? These considerations lead many to a crossroads: should you choose steel or aluminum?

Understanding Steel and Aluminum

To make an informed decision, you need to understand the fundamental properties of both steel and aluminum. You might think of steel as robust and reliable, offering incredible strength. Aluminum, on the other hand, is often viewed as lightweight and corrosion-resistant, making it appealing for various projects.

Properties of Steel

Steel is an alloy made primarily of iron and carbon. Its key features include:

- High Strength: You can rely on steel for heavy-duty applications, as it boasts a high tensile strength.

- Durability: Steel frames can withstand significant stress, making them ideal for structures exposed to harsh conditions.

- Weldability: If you’re into fabrication, steel’s ability to be easily welded allows for intricate designs.

Properties of Aluminum

Aluminum is a lightweight metal known for its versatility and adaptability. Consider these traits:

- Lightweight: It’s significantly lighter than steel, which can be crucial for mobility and ease of handling.

- Corrosion Resistance: Due to its natural oxide layer, aluminum can resist rust and wear over time.

- Workability: Aluminum can be shaped and molded into various forms, making it suitable for creative designs.

Applications: Where Each Material Shines

When contemplating your choice, you should consider how these materials perform in various applications. Both steel and aluminum have their niches, and understanding these can guide your decision-making.

Steel Applications

-

Construction and Architecture: Steel frames are common in skyscrapers and bridges due to their ability to bear heavy loads.

-

Heavy Machinery: Since steel can endure extreme forces, it’s often found in machinery and equipment.

-

Automotive Industry: Steel is extensively used in car manufacturing for body frames and chassis.

Aluminum Applications

-

Aerospace Industry: The lightweight nature of aluminum makes it a preferred choice for aircraft structures.

-

Sports Equipment: Many bicycles and sporting goods use aluminum for its lightness and durability.

-

Consumer Electronics: You’ll often find aluminum in laptops and smartphones, combining aesthetics with functionality.

Pros and Cons of Steel and Aluminum Frames

Now that you know the basics, let’s weigh the pros and cons of both materials. This should help you further clarify your priorities.

Steel Frames

| Pros | Cons |

|---|---|

| Extremely strong | Heavier than aluminum |

| Cost-effective | Susceptible to rust if not treated |

| Highly durable | Less malleable for shaping |

| Excellent weldability | Requires more robust supports |

Steel frames might be your go-to for projects needing exceptional strength and durability. However, you must consider the extra weight and potential for rust if the metal is improperly treated.

Aluminum Frames

| Pros | Cons |

|---|---|

| Lightweight | Generally more expensive than steel |

| Highly corrosion-resistant | Less strength than steel |

| Good thermal conductivity | Can be more challenging to weld |

| Easier to mold and shape | May require additional reinforcements in heavy-load applications |

Aluminum frames shine in applications that require lightweight solutions and corrosion resistance, like in aviation and portable structures. However, if you’re looking for cost efficiency and strength under heavy loads, aluminum might not always be your best option.

Cost Considerations

When assessing your options, pricing is often at the forefront of your mind. Understanding how steel and aluminum stack up in terms of cost can be crucial to your decision.

Price of Steel Frames

Steel frames are often considered more cost-effective than aluminum. This is partly due to the abundance of iron and relatively straightforward production process. When contemplating bulk purchases or large-scale projects, you’ll likely find that using steel could save you a significant amount.

Price of Aluminum Frames

While aluminum frames generally come with a higher price tag, their longevity and lightweight nature can justify the expense. If you’re looking at applications where weight factors significantly impact performance, investing in aluminum may provide long-term savings in efficiency and practicality.

Weight Considerations

The weight of the frame can greatly affect a project’s overall feasibility. Depending on the context in which you’re using the material, being mindful of weight can guide your choice.

The Weight of Steel

Steel, being heavy, might be cumbersome for certain applications, especially if mobility is a priority. However, in fixed structures, the weight can be an advantage, adding stability and strength.

The Weight of Aluminum

Aluminum frames offer an obvious benefit in weight. When building vehicles, bicycles, or even portable structures, this lightness can greatly enhance performance and ease of transport. It’s always essential to weigh these considerations against the structural integrity you require.

Strength and Durability

Can your project withstand the test of time? When choosing your frame material, durability often plays a significant role in long-term value.

The Strength of Steel

Steel is famed for its incredible strength-to-weight ratio. In scenarios requiring load-bearing capabilities, such as high-rise buildings or bridges, steel is often the material of choice. It can absorb high impact forces without significant deformation, leading to longer-lasting structures.

The Durability of Aluminum

While aluminum is not as strong as steel in terms of tensile strength, its resistance to corrosion enhances its durability in certain environments. Structures in coastal areas with high humidity levels may benefit from aluminum frames, as they maintain their integrity where steel would rust.

Environmental Impact

Your choice may also depend on ecological considerations. How do steel and aluminum frame options impact the environment in terms of production, recycling, and overall sustainability?

Steel’s Environmental Footprint

The steel industry is resource-intensive, with significant energy consumption during production. Nevertheless, steel boasts a high recycling rate, retaining a substantial amount of its strength even after multiple recycling processes. This characteristic contributes to its sustainability as a material.

Aluminum’s Environmental Footprint

While aluminum production is energy-intensive, it has a high potential for recycling, often using only 5% of the energy required for primary production. If sustainability is a concern for you, prioritizing materials with high recycling potential may lead you towards aluminum.

Aesthetic Considerations

If you desire a certain aesthetic appeal, the material’s characteristics can influence your choice. You might want to consider how each option fits into the overall design of your project.

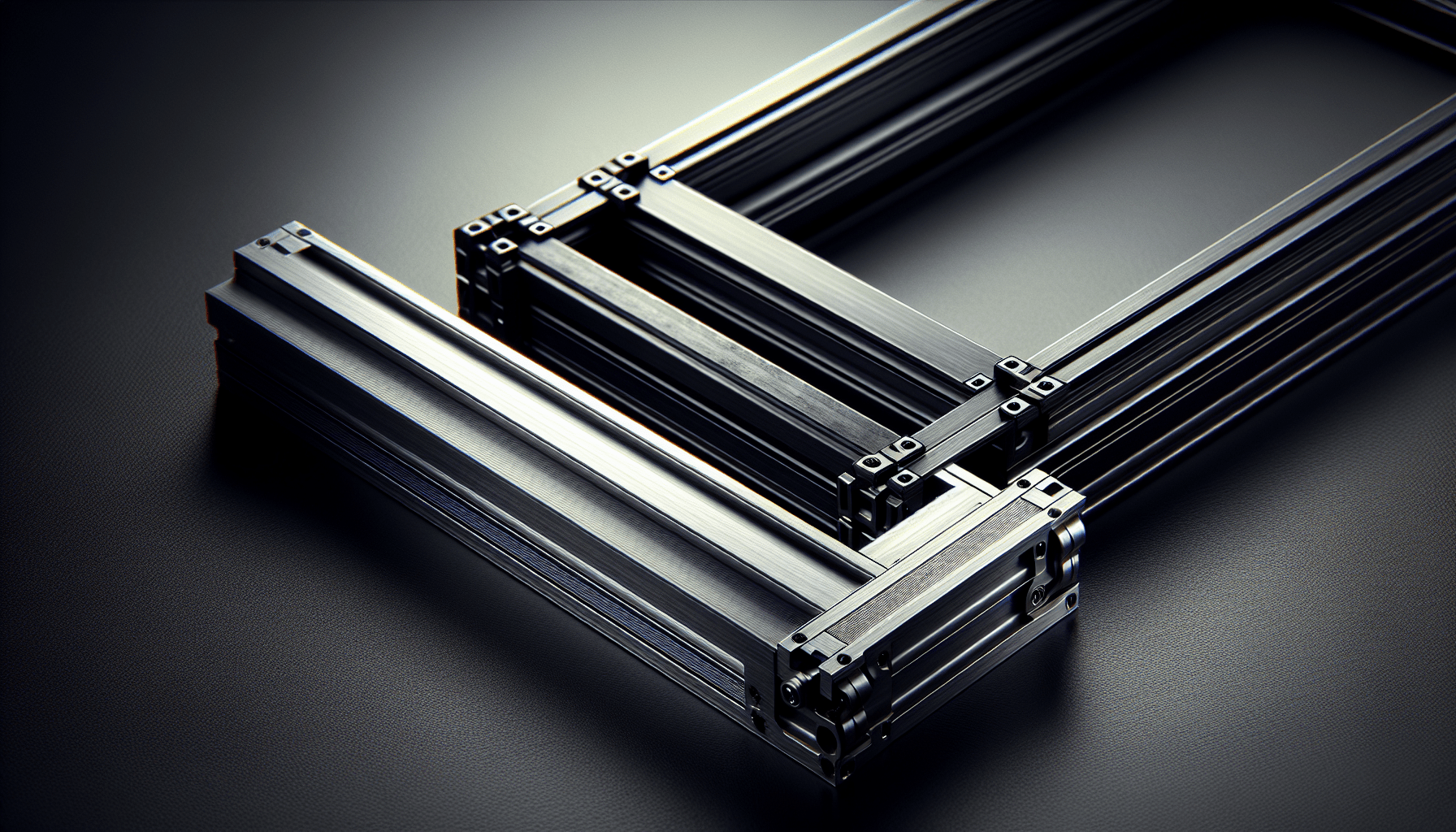

Steel’s Aesthetic Qualities

Steel has a sleek and modern look that fits well into industrial or minimalist designs. You can finish it in a variety of ways, adding to its appeal as part of a visually striking project.

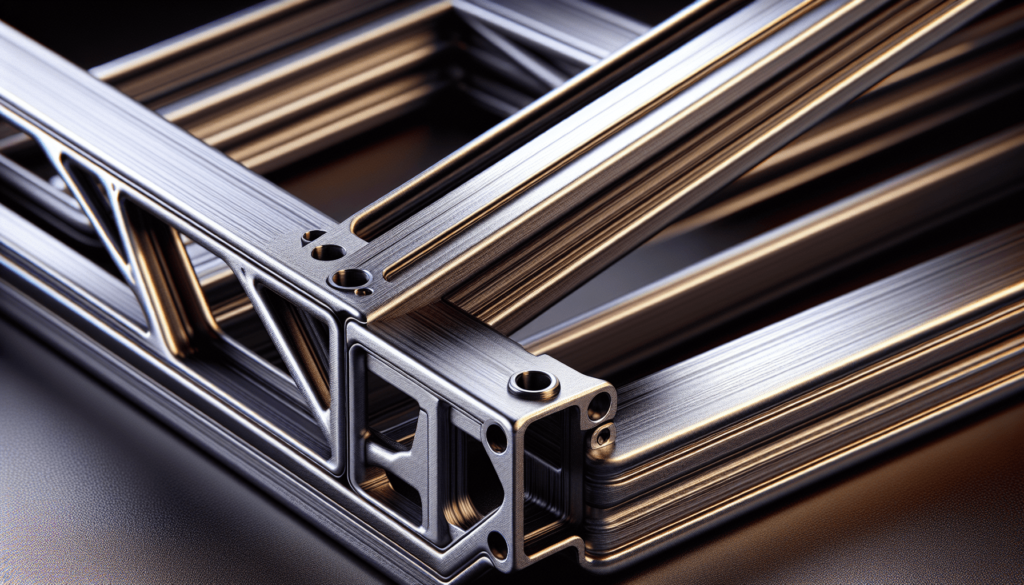

Aluminum’s Aesthetic Qualities

Aluminum’s versatility allows for creative designs, especially in consumer products and architecture. It can also be anodized, allowing a range of colors and finishes. If you’re aiming for a specific visual appeal, aluminum may offer greater flexibility.

Customizability

Are you thinking about a creative project that requires a unique approach? How customizable are these materials?

Customizing Steel Frames

With steel, you have opportunities for creative fabrication and customization, especially through welding and cutting. Its malleable nature allows you to bring complex designs to life. However, you may need skilled professionals to achieve the desired results.

Customizing Aluminum Frames

Aluminum can also be customized effectively, especially in lighter applications. It’s more straightforward to shape into unique forms, but some weakening may occur with intensive modifications.

Safety Considerations

Safety is likely a top priority for you, especially when it comes to long-lasting structures or vehicles made from steel or aluminum.

Safety of Steel Frames

Steel’s strength makes it a reliable option in applications where safety is paramount. For example, in construction, steel frames can withstand forces such as earthquakes, providing an essential safety factor.

Safety of Aluminum Frames

While aluminum is strong, it is generally regarded as less safe than steel in high-stress scenarios. However, innovations in aluminum alloys have made significant strides, improving safety profiles in applicable areas such as aerospace and automotive.

Conclusion: Making the Right Choice

Ultimately, choosing between steel and aluminum frames will depend on your unique needs and priorities. As you reflect upon the aspects discussed—weight, strength, cost, environmental footprint, durability, and aesthetics—you’ll hopefully find clarity in your decision.

Keep in mind that there isn’t a one-size-fits-all answer. Whether you lean toward the robustness of steel or the lightweight versatility of aluminum, you can find solutions catering to your specific project requirements. In the end, it’s about finding the right balance between your goals and the materials at your disposal.